Chain Conveyor Design Manual

The different types of handling equipment can be classified into four major categories. Handling of materials which is an important factor in manufacturing is an integral part of facilities design and the efficiency of material handling equipment add to the performance level of a firm.

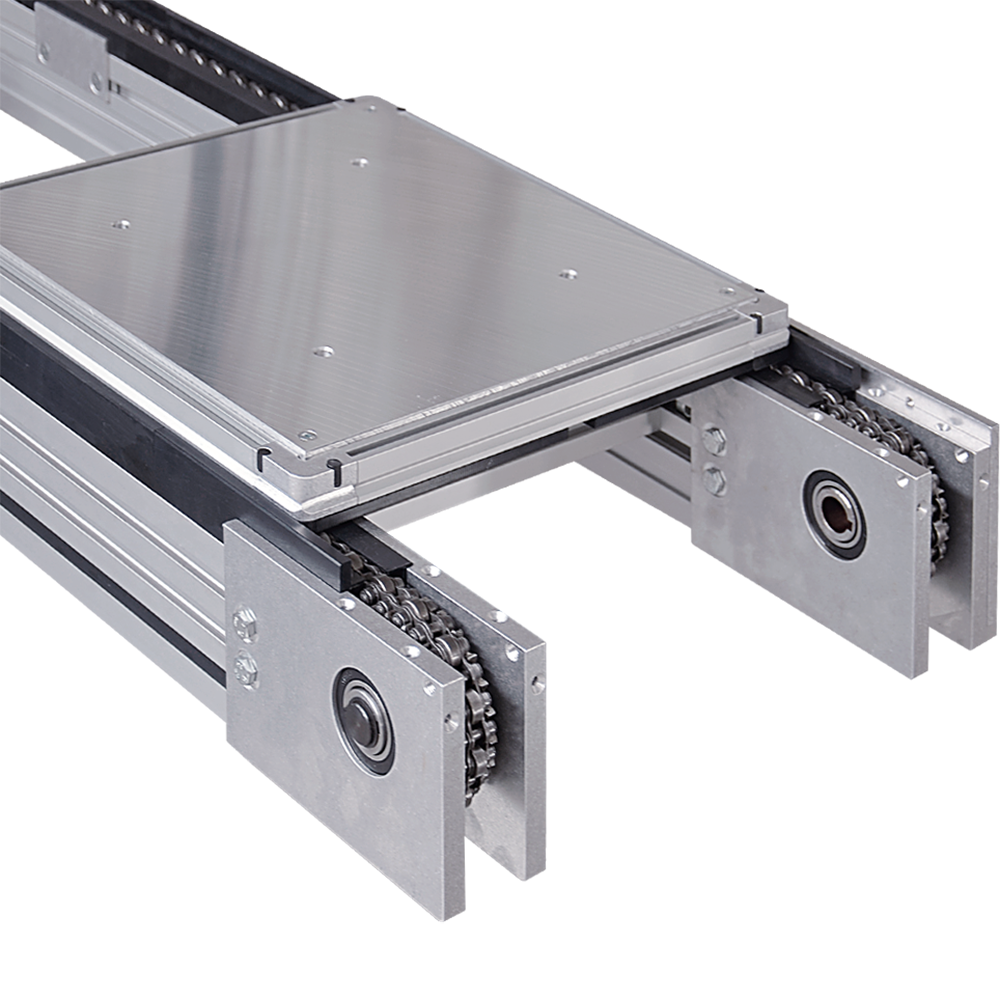

Tku 2040 Indexing Chain Conveyor System Maschinenbau Kitz Gmbh Pdf Catalogs Technical Documentation Brochure

Pallet conveyors are designed to manage heavy loads on pallets or skids.

. The popularity of the chain-driven safety bicycle brought about the demise of the penny-farthing and is still a basic feature of bicycle design today. Log in with Facebook Log in with Google. Based on different principles.

Click here to sign up. Close Log In. Conveyor Chain and Rexnord Conveyor Components.

Because there are so many different variables that need to be considered when thinking about conveyor systems it is useful to weigh all of the available options. Conveyor systems are durable and reliable in materials transportation and warehousing. Dependent on application this may include gravity rollers chain driven live rollers drag chains or heavy-duty slat conveyors supported by appropriate.

Log In Sign Up. Remember me on this computer. If in doubt please consult A.

Noble Son Ltd. Drip lubrication is often required for high-speed conveyors and. Increase conveyor efficiency using dynamic simulation software - Simcad Pro.

Rexnord FlatTop Chain performance is maximized when used with low-friction low-wear Rexnord Chain Guide-return. Inter-warehouse or inter-factory movement is vital to the success and efficient running of any logistics business. Manual lubrication is normally sufficient for slow-speed conveyors.

Not lubricating a chain conveyor is a reasonable option only if one of the special chains sealed joint etc is used. Chain drive was the main feature which differentiated the safety bicycle introduced in 1885 with its two equal-sized wheels from the direct-drive penny-farthing or high wheeler type of bicycle. Before use a competent person shall ensure that all chain slings and components including the shorteners are compatible and that they fit properly without overcrowding.

- Incompatible chain sling components may create a hazard by improperly functioning or failing in service refer AS37752-2014 clause 63. Enter the email address you signed up with and well email you a reset link. Manual lubrication may sometimes be adequate for moderate-speed conveyors but drip or brush lubrication is often needed.

Toyota Supply Chain Management. 1 Lakso 1 Casa Herrera 1 Acrison 1 APEC 1 Hapman 1 Kliklok 1 Belco Packaging 1 North Star Engineered 1 Hoppmann 1 AROL Closure System 1 SIG 1 IWKA 1 Automated Conveyor Systems 1 Velten and Pulver Inc 1 Alvey 1 Preferred Packaging 1 Inline Filling Systems 1 Kaps-All 1 Ermanco 1 FlexLink. Material handling equipment MHE is mechanical equipment used for the movement storage control and protection of materials goods and products throughout the process of manufacturing distribution consumption and disposal.

These leading edge solutions are designed to continuously improve productivity for customers in a variety of industries including automotive food beverage warehousedistribution and container handling. Material handling equipment devoid of manual handling. Omega Design 1 PFM 1 Piab 1 Intralox LLC.

Accumulation Roller Chain Conveyor Nikai Systems

Chain Conveyor Material Handling Capacity 1 50 Kg Per Feet Rs 80000 Unit Id 16166131333

Engineering Manual Incline Or Decline Design Inclined Conveyor

Srf P 2010 Accumulating Roller Chain Conveyor Mk North America

Overhead Chain Conveyor System Conveyor Drive Device For Manual Angle Steel Double Track Carcass Hanging Overhead Conveyor China Painting Line Overhead Track Chain Conveyor Made In China Com

0 Response to "Chain Conveyor Design Manual"

Post a Comment